Industrial Sensors

Inductive proximity sensors

Inductive proximity sensors are the preferred choice for the majority of applications requiring accurate, non-contact detection of metallic objects in machinery or automation equipment. As a pioneer and market leader, Pepperl+Fuchs offers innovative, high quality inductive sensors to meet the needs of the worldwide automation and process control markets. Our experience, flexibility and customer focus continues to allow us to offer custom designed solutions for the most unique and demanding applications.

- Polarity reversal and short-circuit protected

- Connection styles include M8, M12 or terminal connection models

- Models with PVC, PUR or silicon cable

- LED status indication

- Outputs in 2-, 3-, 4-wire DC, AC, NAMUR, and AS-Interface versions

Standard Inductive Sensor Product features

- Analog output models with 4-20 mA output signal

- Integrated speed monitor with up to 100 Hz operation

- Pressure resistant cylinder sensors for up to 500 bar

- Sensors approved for gas and dust Ex zones

- Models with stainless steel sensing face

- Weld resistant designs with PTFE-coated surface

- Reduction factor of 1, all metals sensed at same distance

- Exclusive ferrous and non-ferrous detection models

- Safety function sensors

- Extended temperature range: -40 °C up to +250 °C

- Protective class of up to IP68/ IP69k

(submersible/ high pressure water jet resistant)

Application Specific Inductive Sensor features:

- 12, 18 and 30 mm cylindrical styles of stainless steel or plastic housings

- 5mm thin rectangular and long range 80 mm x 80 mm x 40 mm styles

- Sensor outputs of 3-wire DC and NAMUR output types

- Models with hazardous area approvals

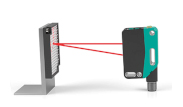

Capacitive Sensors

Capacitive sensors can be used to detect metal objects as well as nearly all other materials. These sensors are often used in applications including level, flow control for detection of liquids, grains and powders.

Standard Capacitive Sensor Product features:

Magnetic Field Sensors

Our magnetic field sensor selection consists of the M12 housing style for traditional magnetic detection applications. Also offered is a non-contact, piston detection sensor for use with steel hydraulic cylinders. These magnetic sensors offer reliable piston magnet detection and are easily mounted, without the need for mounting slots or holes in the cylinder.